Aerodynamic

Mesh Sensor

Mesh Sensor

For Paraglider

Performance

Performance

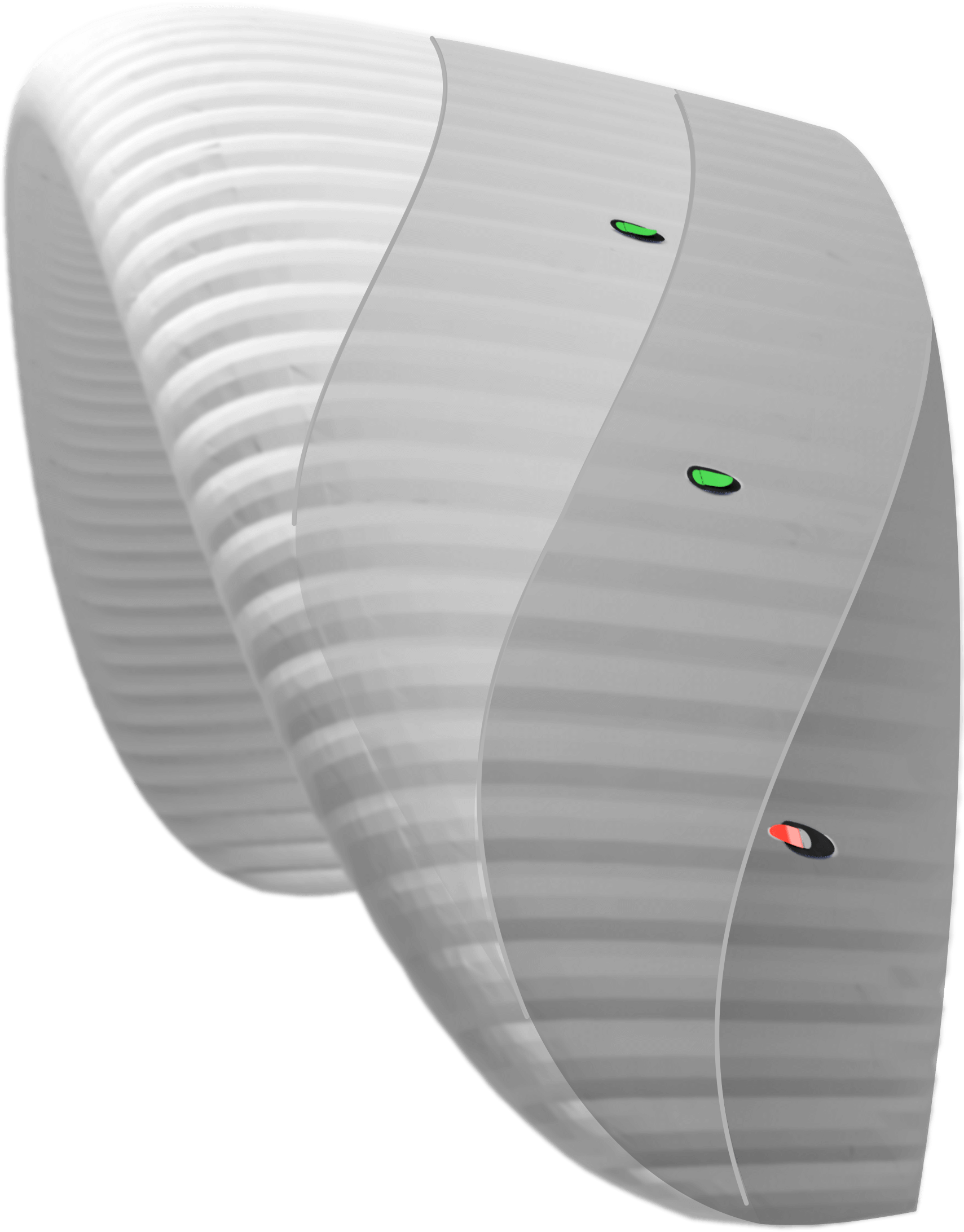

The Aerodynamic Mesh Sensor provides aerodynamic measurement data for the first time – for greater flight safety and significantly extended flight time.

Aerodynamic Mesh Sensor

For Paraglider Performance

The Aerodynamic Mesh Sensor provides aerodynamic measurement data for the first time – for greater flight safety and significantly extended flight time.

Vision

Welcome

to Flysens

The ultra-low power sensor network detects safety-relevant flow values on the wing of a paraglider for the first time. We have developed a sensor system for predictive stall warning, localisation of vertical flows and much more.

Vision

Welcome

to Flysens

The ultra-low power sensor network detects safety-relevant flow values on the wing of a paraglider for the first time. We have developed a sensor system for predictive stall warning, localisation of vertical flows and much more.

EXPLORE SYSTEM

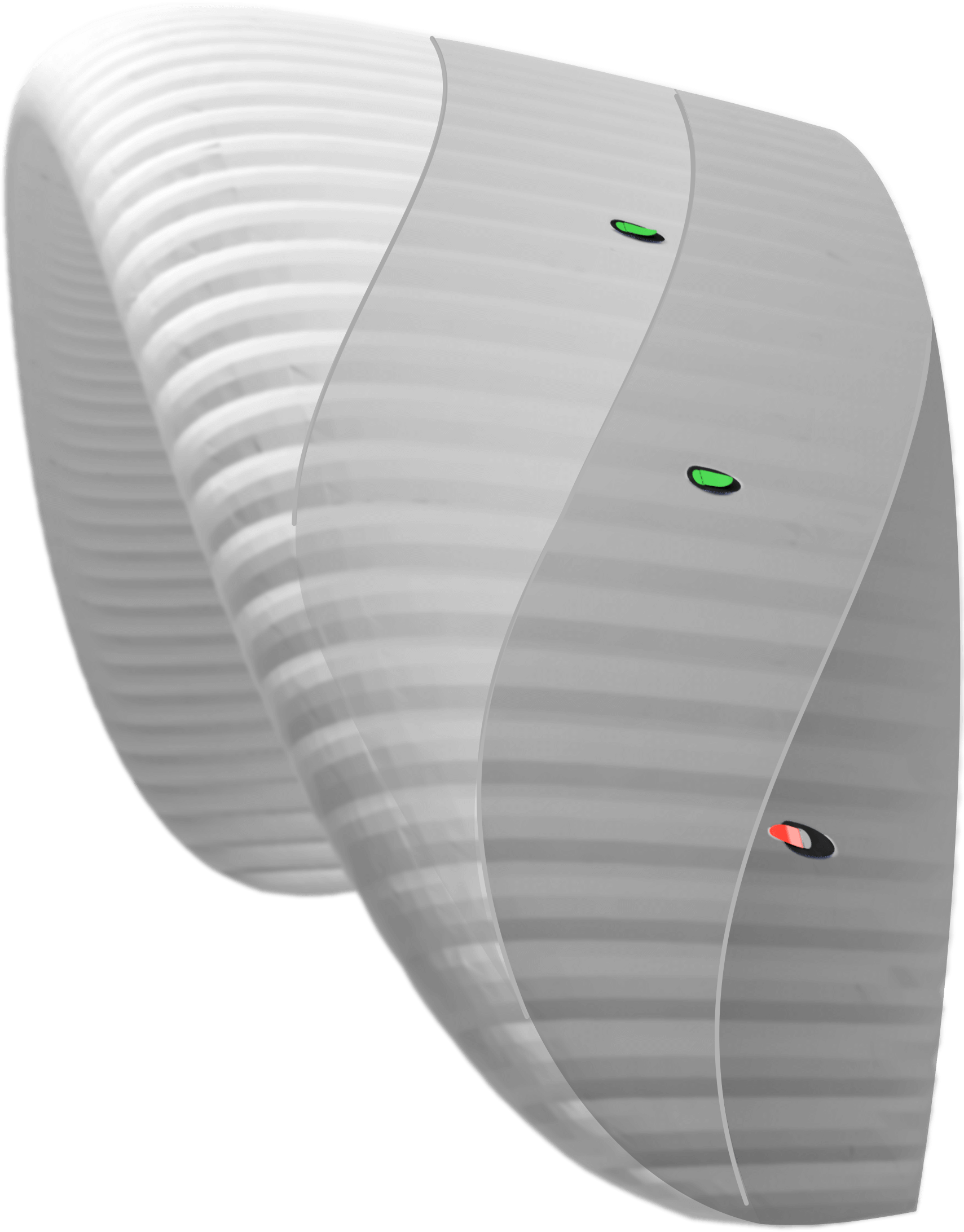

Innovative measuring system

for safe flying

Several AERODYNAMIC MESH SENSORS are attached to the paraglider. Together, these form a sensor data network. This sensor system detects airflow conditions and calculates flight and safety-related information. Information that was previously only simulated in aerodynamic research can now be used for your personal flying experience for the first time.

UNIQUE ADVANTAGE

Predictive stable warning

A stall can occur quickly in emergency situations or due to lack of experience. The predictive stall warning detects this early on and alerts the pilot.

THERMAL LOCALISATION

‘Falling out of thermals’ or ‘circling around the core’ no longer happens. Six pressure and temperature sensors precisely determine the gradient for accurate localisation of a vertical current.

MICRO BACKFLOWS

Even simple curved flight requires a highly complex sequence of movements. Our sensor network detects even the smallest flow disturbances. You gain precise insights into your flight behaviour and can significantly extend your flight time.

EXPLORE SYSTEM

Innovative

measuring system

for safe flying

measuring system

for safe flying

Several AERODYNAMIC MESH SENSORS are attached to the paraglider. Together, these form a sensor data network. This sensor system detects airflow conditions and calculates flight and safety-related information. Information that was previously only simulated in aerodynamic research can now be used for your personal flying experience for the first time.

UNIQUE ADVANTAGE

Predictive

stable warning

A stall can occur quickly in an emergency situation or due to lack of experience. The predictive stall warning detects this early on and alerts the pilot.

THERMAL LOCALISATION

‘Falling out of thermals’ or ‘circling around the core’ no longer happens. Six pressure and temperature sensors precisely determine the gradient for accurate localisation of a vertical current.

MICRO BACKFLOWS

Even simple curved flight requires a highly complex sequence of movements. Our sensor network detects even the smallest flow disturbances. You gain precise insights into your flight behaviour and can significantly extend your flight time.

EXPLORE SYSTEM

REVOLUTIONARY FLIGHT DATA

Through a networked sensor system

ENERGY EFFICIENCY

Over 1,000 hours of flight time

with one button cell battery

ULTRALIGHT

Barely heavier than two sugar cubes

EXPLORE SYSTEM

REVOLUTIONARY FLIGHT DATA -

Through networked

sensor system

ENERGY

EFFICIENT

Over 1,000

flight hours with

just one

button cell battery

ULTRALIGHT

Barely heavier

than two

sugar cubes

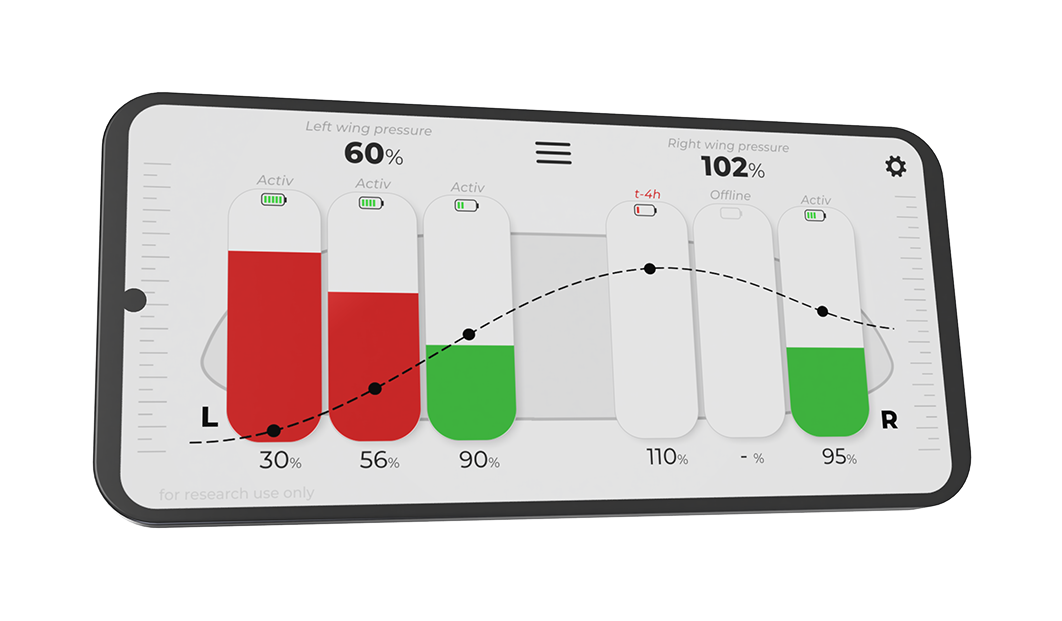

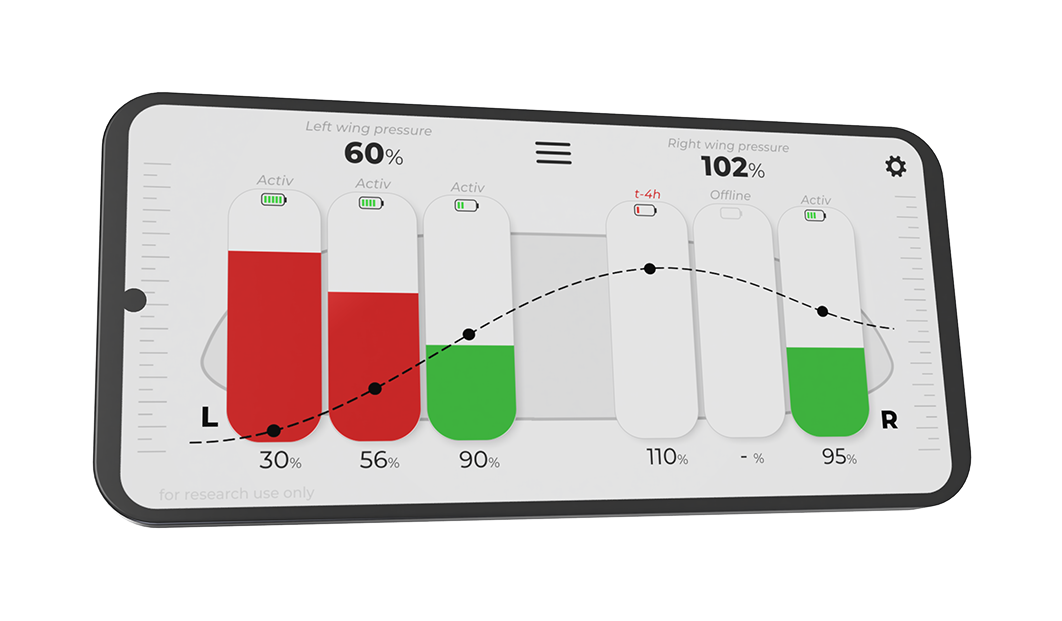

USER INTERFACE

Mesh data computing and user interface for the pilot

Flight-related information is collected by six sensors on the upper wing and two sensors inside the wing and sent to the user interface. This analyses the sensor data and provides the pilot with all the important information.

Braking on one or both sides changes the angle of attack of the paraglider relative to the airflow. If the flight speed is too low or the angle of attack is too high, the backflow spreads across the upper wing from back to front.

The sensors are activated as soon as a reverse flow occurs. The green measurement bars indicate minor micro-disturbances; as soon as the bar turns red, caution is advised as a flow separation is imminent.

Originally derived from aerodynamic research, the pilot receives important information about the pressure distribution on the upper sail. This is where it gets exciting – let yourself be surprised.

USER INTERFACE

Mesh data computing and user interface for the pilot

Flight-related information is collected by six sensors on the upper wing and two sensors inside the wing and sent to the user interface. This analyses the sensor data and provides the pilot with all the important information.

Braking on one or both sides changes the angle of attack of the paraglider relative to the airflow. If the flight speed is too low or the angle of attack is too high, the backflow spreads across the upper wing from back to front.

The sensors are activated as soon as a reverse flow occurs. The green measurement bars indicate minor micro-disturbances; as soon as the bar turns red, caution is advised as a flow separation is imminent.

Originally derived from aerodynamic research, the pilot receives important information about the pressure distribution on the upper sail. This is where it gets exciting – let yourself be surprised.

aerodynamics

Predictive backflow warning

by detecting backflow

Backflow occurs when the paraglider is braked too hard or flown too slowly. In extreme cases, this can lead to a stall or full stall. Backflow therefore indicates that the glider is overloaded and needs more speed. The separation of the adjacent airflow occurs continuously and can be divided into three zones.

Safe zone

Micro backflow

Micro-backflows on the outer sail occur frequently and are not dangerous. Excessive initiation of a turn or brief overbraking can activate the sensor (red). Similarly, turbulence caused by thermals can briefly trigger a sensor. However, if the backflow in the SAFE ZONE lasts for more than two seconds, it will gradually spread into the CAUTION ZONE.

caution zone

Midi backflow

If reverse flow occurs in the CAUTION ZONE, the pilot should already be alert. Prolonged overbraking on one or both sides already reduces the stability of the wing. Control forces can be significantly reduced. The internal pressure of the wing decreases progressively. A wing stall can still be prevented at this point. However, if the situation does not change, the backflow will reach the STALL ZONE.

stable zone

macro backflow

When macro-backflow occurs, the flight speed has already been reduced for several seconds. The angle of attack is very large. The control forces have already decreased further. A one-sided or two-sided stall can occur at any time. Unless landing is imminent, the pilot is in mortal danger.

For the first time, pilots can see local flow fields and angle of attack changes with AERODYNAMIC MESH SENSORS.

System Properties

System Features

Aerodynamic Mesh Sensor

General

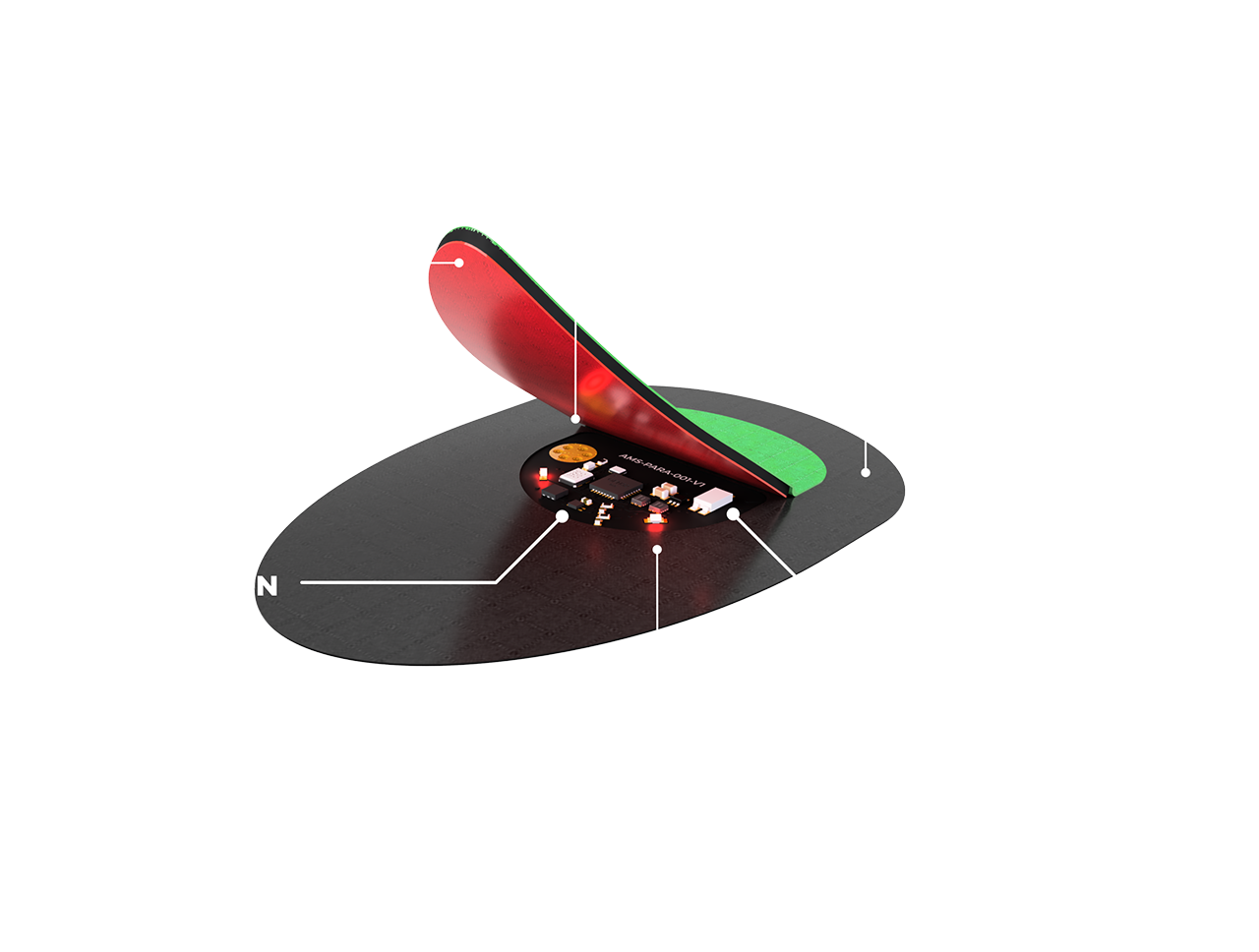

Attaching the sensors

The measuring points are attached to the upper sail of the paraglider using self-adhesive ripstop fabric. If you wish, we will be happy to do this for you.

Paraglider classes and sizes

The attachment point is defined as a percentage of the wingspan and a percentage of the wing depth, and is therefore independent of the paraglider size or class.

Sensor location

A positioning of ±20 cm is sufficient. Paraglider upper sail with backflow zones and the sensor array. Two sensors are located on the profile ribs in the inner sail.

System features

Constructed from ripstop fabric

A precise selection of selected materials protects the electronics in all conditions.

Weight of a sensor

With just a few grams, we reach the weight of two sugar cubes.

Dimensions

80 mm x 40 mm x 3 mm

Battery life

Approximately 1,000 hours with a CR2025 button cell battery

Auto Power ON

The entire sensor system switches itself on and off automatically.

Flow sensor

Detection of backflow using Aeroflap.

Multiple pressure sensors

Absolute pressure sensors and differential pressure sensors with a resolution of <10 cm.

Multiple temperature sensors

Precise temperature sensors detect temperature differences.

User Interface

The Android app has all the important information.

Mesh Data Computing

Algorithms combine the sensor values into a complete system.

aerodynamics

Predictive backflow warning

by detecting backflow

Backflow occurs when the paraglider is braked too hard or flown too slowly. In extreme cases, this can lead to a stall or full stall. Backflow therefore indicates that the glider is overloaded and needs more speed. The separation of the adjacent airflow occurs continuously and can be divided into three zones.

Safe zone

Micro backflow

Micro-backflows on the outer sail occur frequently and are not dangerous. Excessive initiation of a turn or brief overbraking can activate the sensor (red). Similarly, turbulence caused by thermals can briefly trigger a sensor. However, if the backflow in the SAFE ZONE lasts for more than two seconds, it will gradually spread into the CAUTION ZONE.

caution zone

Midi backflow

If reverse flow occurs in the CAUTION ZONE, the pilot should already be alert. Prolonged overbraking on one or both sides already reduces the stability of the wing. Control forces can be significantly reduced. The internal pressure of the wing decreases progressively. A wing stall can still be prevented at this point. However, if the situation does not change, the backflow will reach the STALL ZONE.

stable zone

macro backflow

When macro-backflow occurs, the flight speed has already been reduced for several seconds. The angle of attack is very large. The control forces have already decreased further. A one-sided or two-sided stall can occur at any time. Unless landing is imminent, the pilot is in mortal danger.

For the first time, pilots can see local flow fields and angle of attack changes with AERODYNAMIC MESH SENSORS.

System Properties

System Features

Aerodynamic Mesh Sensor

General

Attaching the sensors

The measuring points are attached to the upper sail of the paraglider using self-adhesive ripstop fabric. If you wish, we will be happy to do this for you.

Paraglider classes and sizes

The attachment point is defined as a percentage of the wingspan and a percentage of the wing depth, and is therefore independent of the paraglider size or class.

Sensor location

A positioning of ±20 cm is sufficient. Paraglider upper sail with backflow zones and the sensor array. Two sensors are located on the profile ribs in the inner sail.

System features

Constructed from ripstop fabric

A precise selection of selected materials protects the electronics in all conditions.

Weight of a sensor

With just a few grams, we reach the weight of two sugar cubes.

Dimensions

80 mm x 40 mm x 3 mm

Battery life

Approximately 1,000 hours with a CR2025 button cell battery

Auto Power ON

The entire sensor system switches itself on and off automatically.

Flow sensor

Detection of backflow using Aeroflap.

Multiple pressure sensors

Absolute pressure sensors and differential pressure sensors with a resolution of <10 cm.

Multiple temperature sensors

Precise temperature sensors detect temperature differences.

User Interface

The Android app has all the important information.

Mesh Data Computing

Algorithms combine the sensor values into a complete system.

Kontakt

We're here for you

Kontakt

We're here for you

Flysens

- Bußmatten 21

- 77815 Bühl

- Tel: +49 176 72317782

- Mail: info(at)flysens.de

Flysens

- Bußmatten 21

- 77815 Bühl

- Tel: +49 176 72317782

- Mail: info(at)flysens.de